Basic hydraulics: simplifying waste and recycling work

Hydraulics have proven to be a versatile and effective technology in various industries, providing precise control, reliability and extraordinary power density. Some industries are lightly equipped with hydraulic equipment, such as automation and food and beverage. By contrast, hydraulics absolutely dominate other areas, including waste management and recycling.

Waste

management and recycling is a general term to describe the process and

machinery used by municipalities to collect and process garbage, waste and

recycling. It starts at your home or workplace, where our walk-in cleaners drop

your bags or drop your containers into their trucks for transport to transfer

stations before they are unloaded and processed on-site.

Various

materials, from electronics to organic waste, are sorted before being

transported to landfills or recycling facilities. It is no exaggeration to say

that we take waste management for granted, because it is an essential aspect of

urban life and plays an essential role in maintaining public health and

environmental sustainability.

Power and precision of hydraulic motor.

One of the

most well-known applications of hydraulics in waste management is in waste

collection trucks, also known as garbage, garbage or sanitation trucks. Garbage

trucks, whether front-, rear- or side-loading, rely on hydraulic systems to

lift and empty containers, compact waste and empty it at the transfer station.

The hydraulic system is equipped with a Rexroth hydraulic

pump mounted on the transmission PTO or on the crankshaft.

There are

many styles of garbage trucks, but the most common is the rear loader. Rear

loader trucks provide a large hopper for workers to dispose of garbage or

recycling. When the hopper is full, the familiar lever-operated valves (or now,

more commonly, buttons) on the side of the truck are operated, and the

compactor lowers and pulls the waste into the body where it is compacted. This

style of truck also unloads its load much like a dump truck, using a

telescoping hydraulic cylinder to tilt the load to be unloaded at the transfer

station.

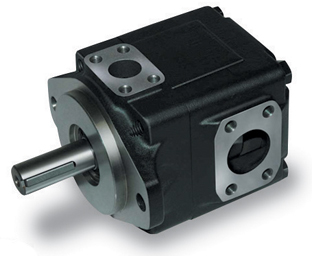

Most other

garbage collection vehicles operate with a single driver and pick up or empty

bins and containers using Rexroth

hydraulic motors. Many commercial or industrial buildings avoid

curbside collection altogether and instead use bulky steel bins or large

plastic bins. Steel containers are transported or unloaded by front-load,

roll-off or grapple trucks, which is more common in non-governmental commercial

collection operations.

Front-loading

trucks use tusk-shaped forks, which are extended down and out by hydraulic

cylinders before the operator moves forward to insert the forks into the

container lift slots. Again, with the cylinders, the load is lifted and

reversed to the top, where it is unloaded into the body. The operator often

activates control valves (or switch) to shake the container and loosen the

waste stuck to the sides and bottom, often creating a cacophony that is all too

familiar to apartment dwellers.

Other common

commercial dump trucks are hook and hook lift configurations. The grapple truck

offers one of the largest payloads, being able to haul huge waste containers or

large items to the platform using the grapple and (you guessed it) hydraulic

winch system. A hook lift truck looks similar but operates with a hydraulic

hook that extends to grab the front edge of the container and pull it toward

the structure.

Hydraulic

systems are unique actuators for garbage trucks due to the high power-to-weight

ratio of the hydraulic cylinders that turn heavier containers into

"waste," which can be easily lifted and unloaded. Finally, the

precise control provided by hydraulic systems allows operators to perform these

tasks accurately and reliably, ensuring efficient waste collection.

The modern

hydraulic technology that seems ideal for waste collection is the hybrid

hydraulic system. The use of a hydraulic

pump/motor unit and a series of hydro-pneumatic accumulators provides a

robust and efficient way to recover kinetic energy during frequent stops. The

inertia of the braking vehicle drives the pump to direct hydraulic energy to

the accumulators. When the driver accelerates, the pump rotates toward the

center to act as a motor that harnesses stored hydraulic energy to help

accelerate the truck.

Compact and easily sorted

Waste

compactors are essential to reduce the volume of waste before disposal, making

waste management more efficient and reducing the frequency of landfills.

Hydraulic compactors use powerful hydraulic cylinders to compress waste

materials, reducing their volume and making transportation and disposal easier.

Without a compactor, a garbage truck would only be able to move a dozen houses

worth of trash. The compressor increases the load to several thousand pounds

and sometimes ten tons or more.

Comments

Post a Comment